Realizing your production’s full potential –

through expert training for your employees

Realizing your production’s full potential –

through expert training for your employees

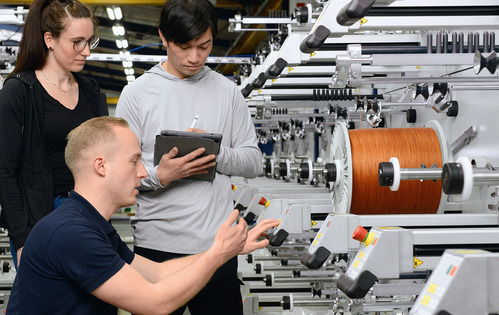

With precision winders from SAHM, your production starts from a very strong position. But any production machinery is only as effective as the operators or maintenance staff who are working with it. To tap the full potential of your high-tech machinery, you also need employees who have received the necessary training to work with this specialized equipment.

The SAHM Academy makes this possible with training courses, workshops and online programs that are customized to meet the qualification requirements of your staff on an individual and modular basis.

What does this mean for your company? Increased production efficiency, reduction of unplanned downtimes, improved product quality, and more highly motivated employees. Top training for your team is a key element of maximizing production performance.

You're interested in organizing further training for your employees and realizing the full potential of your company? Give us a call or send a message. We'll be pleased to inform you about our individual training offerings. |

Service hotline +49 5651 804-256service@sahmwinder.com |

Training: On-site or at our training center

SAHM’s training programs are based on the latest product and application knowledge and are continuously being updated. The SAHM Academy can provide a comprehensive package of training services covering everything from engineering basics, to specific applications, to specialized machine operation, to full maintenance of all mechanical and electronic components in SAHM winders.

- Training is available at the SAHM Academy training center in Eschwege, Germany, or at your company

- Training courses in connection with factory acceptance testing

- Combined theory and practice directly on the machines with experienced trainers

- Limited number of participants for optimal learning results

- SAHM Training Certificate

Fernando Eblagon, Portugal

SUPERVISOR TRAINING

SUPERVISOR TRAINING

- Safety at the machine

- Advanced HMI training

- Process monitoring and error detection

- Training of your own personnel

- Determining winder parameters and material characteristics

- Optimizing package quality

- Adjusting package characteristics for optimal downstream processing

- Understanding and making the most of winder features

OPERATOR TRAINING

OPERATOR TRAINING

- Safety at the machine

- HMI basics

- Getting the winder ready for production

- Safe machine operation

- Setting up the winding material

- Process monitoring and error detection

- Handling and storage of finished bobbins

WINDING TECHNOLOGY

WINDING TECHNOLOGY

- Basics of winding technology

- Determining and converting winding ratios

- Winder potential and setting of options for optimized winding results

- Parameterizing and optimizing bobbin changes

MECHANICAL MAINTENANCE TRAINING

MECHANICAL MAINTENANCE TRAINING

- Inspections

- Planned maintenance

- Cleaning intervals for winders and individual components

- Error detection, diagnosis and correction

- Spotting worn-out components

- Winder optimization and overhaul

- Disassembly and assembly of a complete winding head

- Fine adjustment of process-specific components

ELECTRICAL MAINTENANCE TRAINING

ELECTRICAL MAINTENANCE TRAINING

- Inspections

- Planned maintenance

- Replacement and adjustment of electronic components

- Error detection, diagnosis and correction

- Taking measurements on electronic components

- Software updates

- Precise error analysis

- Calibration of electronic components

SAFETY

SAFETY

- Mechanical hazards

- Electrical hazards

- Thermal hazards

- Hazards from noise

- Hazards from rotating machine elements

- Evaluating hazards and determining risks

- Safe working practices at the winder

Modules are presented as examples. Available training content is flexible and can be adjusted to fit your individual requirements.

Online training

Take advantage of our digital training support via chat and video conferencing. In online training sessions customized to your requirements, we can stream our expert knowledge directly to your production. You can benefit from our know-how anywhere in the world.

- Training at the workplace or to employees’ remote locations

- No travel costs or absences

- Online training customized to your needs

- Personal support

- SAHM Training Certificate

- Online factory acceptance testing including employee training

SUPERVISOR TRAINING

SUPERVISOR TRAINING

- Safety at the machine

- Advanced HMI training

- Process monitoring and error detection

- Training of your own personnel

- Determining winder parameters and material characteristics

- Optimizing package quality

- Adjusting package characteristics for optimal downstream processing

- Understanding and making the most of winder features

WINDING TECHNOLOGY

WINDING TECHNOLOGY

- Basics of winding technology

- Determining and converting winding ratios

- Winder potential and setting of options for optimized winding results

- Parameterizing and optimizing bobbin changes

SAFETY

SAFETY

- Mechanical hazards

- Electrical hazards

- Thermal hazards

- Hazards from noise

- Hazards from rotating machine elements

- Evaluating hazards and determining risks

- Safe working practices at the winder

Modules are presented as examples. Available training content is flexible and can be adjusted to fit your individual requirements.

Consulting

You’re interested in optimizing or expanding your production activities? Or would like to establish a new production plant? With the SAHM Consulting service, we can provide you with comprehensive technical expertise and practical, on-site support. With our integrated understanding of systems and processes, we can help to identify new potential for your production and offer solutions for all activities connected with the winding process.

- Hands-on expert consulting at your site

- Identification of possible improvements

- Support for start-ups dealing with topics such as "winding processes" and "fiber development and characteristics"

We can serve as expert consultants for you in realizing the full potential of your winding processes as well as upstream and downstream production areas. Call us or send us a short message. We will be in touch with you promptly! |

Service hotline +49 5651 804-256service@sahmwinder.com |